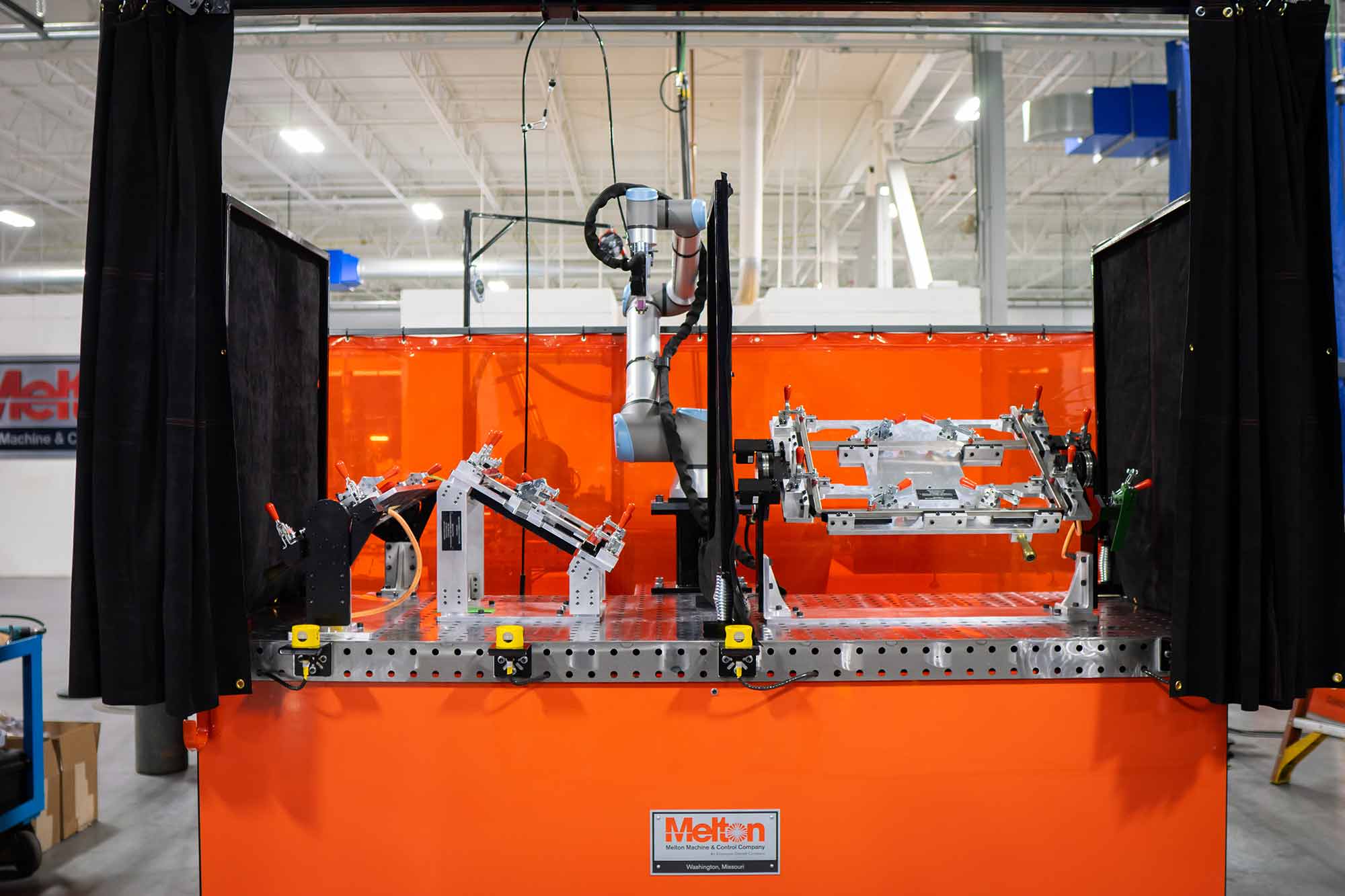

Collaborative Robot Welding System

Making Automation Easy

Systems can be set up for:

- Tack-Welding

- Weaving

- Linear Welds

- Circular Welds

- Stitch Welding

- Patterns

Benefits

- MMCC software makes it easy to program in less than 20 min

- Quick deployment

- Flexible for different sizes, shapes and applications

Available With

- Universal Robots UR20, UR10e or UR5e

- GTAW sets for TIG welding of mild steel, stainless & aluminum

- Miller Maxstar & Dynasty 280, 300, 400 & 800

- Miller Power Source includes: DC GTAW, Pulsed TIG (GTAW-P)

- Coolmate™ 1.3 Water Cooler

- Water-Cooled Torch

- Gas Hose with Flowmeter

- Melton’s software application (CAP)

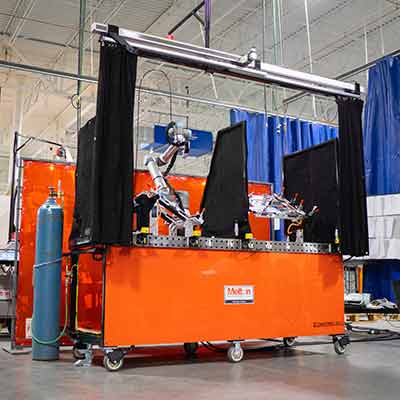

- Carts for single or 2 station applications

- 36 x 48 Single cart unit

- 36 x 96 Double cart unit

- Custom sizes & mounting options available

Options and Service

- Arc shields

- Variety of torches

- Tooling to hold your parts

- Training and on-site support available

- Rail system for additional reach

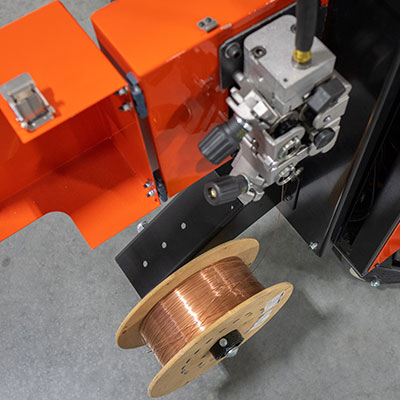

- Wire Feed